Roof Coating vs Liquid Applied Membrane

Roof Coating vs Liquid Applied Membranes:

For a very long time, coatings have been employed in the building and roofing sectors. From beeswax and pitch some 5000 years ago to lacquers and varnishes just a few thousand years ago, to our present polymer-based products, they have been manufactured from a variety of diverse ingredients. The development of polymers has, in the past 40 years, led to "the most dramatic gain in coating qualities," according to the Roof Coating Manufacturers Association. For example, plaza decks, parking garages, balconies, playgrounds, and roofs are coated with polymer-based materials to offer a degree of water resistance and an aesthetically beautiful surface. The water-proofing layer for brand-new roofs, roof replacements, and roof re-cover systems is made of polymer-based liquid applied membranes. Acrylics, silicones, and urethanes are some of the popular polymer-based materials.

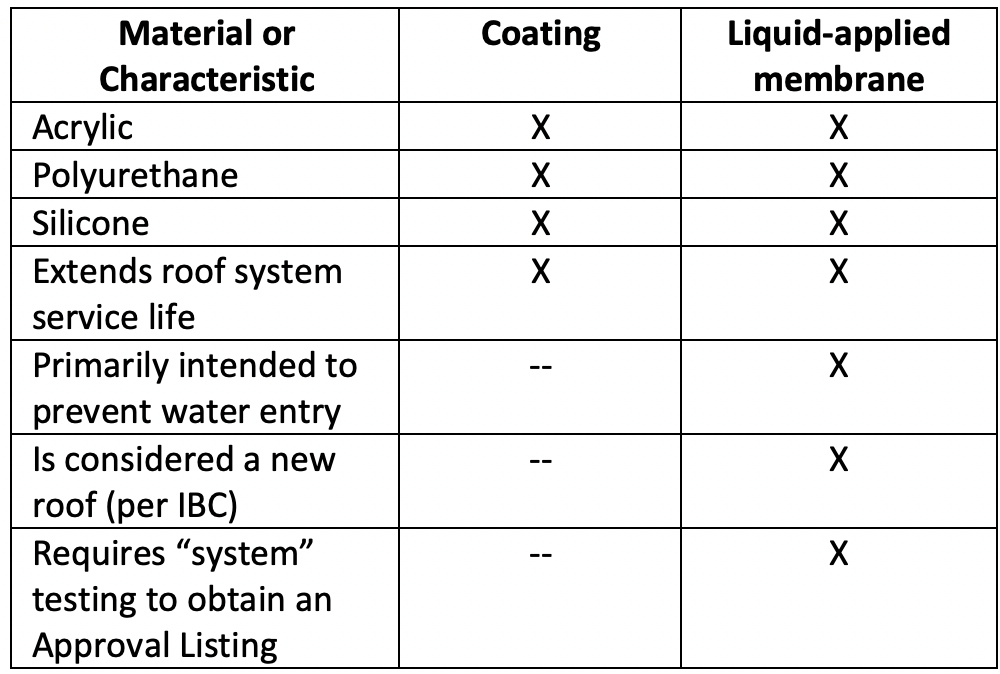

These polymers are in the spotlight because we frequently use the materials we use for coatings as liquid applied membranes. When both applications employ essentially the same set of materials, how can we classify and characterize these various installations that have various intended uses? This blog examines the distinctions and similarities between the two product categories—coatings and liquid applied membranes—in great detail. And maybe to shed some light on the definitions and application of such terminologies.

Understanding the terms currently being used in the business will assist clarify the differences between coatings and liquid applied membranes. Since it is thought to be consensus-based, the International Building Code (IBC) is a suitable place to start.

The term "liquid applied membrane" is not defined in the International Building Code, but the term "coating" is.

"COATING FOR ROOFS a fluid-applied, adherent coating used for roof upkeep or repair, or as part of a roof assembly or roof covering system."

Four aspects are revealed by the IBC's definition of roof coating.

- Fluid application and adhesion of coatings (to a substrate)

- Coatings are utilized for upkeep or repair.

- In order to remedy damage or restore pre-damage condition, "Roof Repair" is described as "Reconstruction or renewal of any component of an existing roof."

- Coatings may be a part of a roof assembly or roof system (which, under ICC criteria, are the same thing).

- "A system created to offer weather protection and resistance to design loads is referred to as a "roof assembly." The roof covering, roof deck, or a single component that serves as both the roof covering and the roof deck make up the system. Underlayment, a thermal barrier, insulation, or a vapor retarder can all be found in a roof assembly."

- According to the definition, "Roof Covering" refers to any covering used to improve the appearance, weather resistance, or fire classification of a roof.

- According to IBC, a "Roof Covering System" is a "Roof Assembly."

Except for the fact that coatings are meant for maintenance and repair, the IBC's definition of roof coating doesn't really bring us any closer to separating coatings and liquid-applied membranes. In addition, the IBC defines coatings as having the ability to "correct damage or restore pre-damage condition" during roof repairs, despite the fact that this is not how they are typically meant to be utilized.

"A liquid membrane roofing system: what is it?"

A fully adherent, seamless, and self-flashing membrane is created by the combination of several parts that make up a liquid applied roofing system. To design a real liquid membrane system that maintains and safeguards the structural integrity of the structure, components include mesh membranes and liquid applied coatings." Here are some illustrations of popular products.

"A roof coating system: what is it?"

Roof Coatings are specially formulated to extend the life of roofs while protecting them from harmful weather and environmental factors like UV light, water, and wind. Roof coatings in a variety of different technologies such as acrylic, silicone, and polyurethanes to meet a variety of building needs and budgets.

Like any other conventional membrane-type roof system, a liquid-applied roofing membrane safeguards the structure of the building, and coatings are made to increase the lifespan of structurally sound roofs.

A roof coating is described in detail by the Roof Coating Manufacturers Association (RCMA). To distinguish roof coatings from what is typically referred to as "paint," the RCMA is correctly focused on the makeup of a coating (i.e., increased solids content, high quality resins). One idea from the RCMA sticks out in particular: since roof coatings are "elastomeric and durable films," they give "an additional degree of waterproofing" and can "bridge minor gaps and membrane seams," among other benefits. The roofing industry is aware of a coating's potential to offer some weather resistance and restorative qualities, but it is challenging to test for and quantify this property (i.e., crack bridging). A roof coating is primarily designed to increase the service life of structurally sound roofs, not necessarily to serve as the waterproofing layer, and it bears repeating. A liquid-applied membrane is designed to do that.

Conclusion

Simply put, coatings are used to provide protection from the elements and help extend service life. Coatings are not installed as 'membranes' so they are not intended to seal leaks or be considered "waterproof". Liquid applied membranes are considered to be just that—membranes—and are used as the covering in new and re-cover roof systems. Liquid applied membranes are tested as systems and have approval listings just like traditional asphaltic, modified bitumen, and single-ply roof systems.

References For This Article:

RCMA.org/history-of-roof-coatings

https://codes.iccsafe.org/content/IBC2018/chapter-15-roof-assemblies-and-rooftop-structures